Companies have to comply with a number of labeling requirements on the manufacturing floor. These rules are put in place to make sure cases and boxes can be processed, shipped, and tracked efficiently, but this only works if the labeling is done properly.

Many manufacturers continue to rely on outdated labeling technology that print illegible labels or place them incorrectly, creating costly errors. Charge-backs and other problems with shipping and handling can quickly add up and hurt a company’s bottom line.

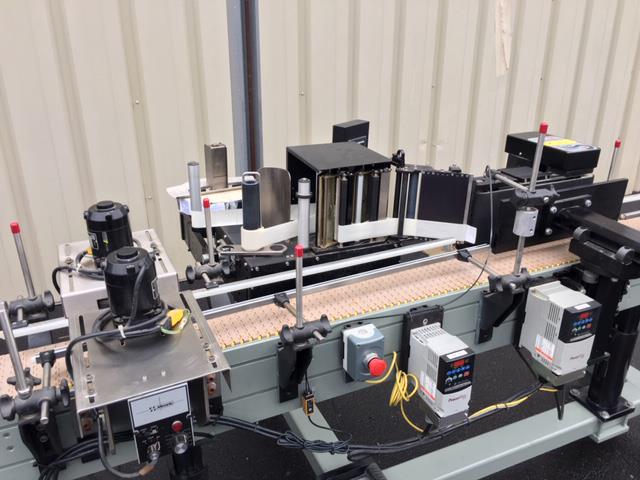

High-performance box labeling machines can be used to print and quickly apply crisp, clear labels to cases and boxes at a low cost, helping companies prevent errors and improve supply chain efficiencies.

Learn more about our customizable labeling machines here.

Benefits of Case Labelers and Box Labeling Machines

Paragon Labeling Systems prides itself on the reliability and modularity of our labeling machines, the low cost of ownership, and the strong return on investment they provide.

Each one of our labeling machines has a user-friendly interface and robust build to withstand the harsh conditions of the manufacturing floor. A full line of field interchangeable application modules allows you to configure your labels for a number of applications and customize your machine to your manufacturing processes.

Labels are applied quickly and accurately, helping you improve efficiencies and lower costs.

Paragon Labeling Machines for Cases and Boxes

- PLS 100 – The premier decorative labeling solution for applying pre-printed labels onto products, cartons, cases, totes, or pallets.

- PLS 400 Plus – A premier print and apply labeling solution with barcode and/or RFID capabilities that can grow and adjust with your business and industry.

- PLS 500 – The ultimate label application solution, dedicated to maximizing organizations’ productivity with superior quality and integration.

Contact our labeling experts to learn more about our labeling machines or to request a personalized demo.

Case Labeling FAQs

What is a case label?

Cases are considered an individual logistics unit, so they will need a Serial Shipping Container Code (SSCC) that “acts as a license plate to track a shipment of logistics units through the supply chain.”

Case labeling best practices

Similar to pallet labels, case labels should be made of a hardy material that can withstand the harsh environments a case may experience as it moves through the supply chain. Labels should also be crisp with clear printing so employees and scanners can easily read the information and process it accurately.

Labels should be applied smoothly onto the case or box, without wrinkles, so that scanners can easily read the information printed. According to gs1us.org, each case should have at least one barcode, but it is recommended to add another on the adjacent side so it can be easily scanned if turned sideways in a truck or warehouse rack.