Labeling Considerations for Meat and Produce

Meat and produce have specific labeling requirements that must be followed to help customers make informed decisions about the food they consume and allow for traceability in the supply chain. Labeling errors can lead to costly recalls that hurt the already-thin margins of meat and produce suppliers.

The companies that supply these food products need to be aware of the specific produce labeling or meat labeling requirements, ensure they are being met, and apply the correct labels as quickly and accurately as possible. This labeling guide includes an overview of what suppliers need to know to streamline this labeling process.

What are the mandatory labeling requirements for meat?

The U.S. Department of Agriculture (USDA) provides guidelines for labeling meat, poultry, and egg products.

USDA meat labeling requirements for the product label include:

- product name

- inspection legend and establishment number

- handling statement

- net weight statement

- ingredients statement

- address line

- nutrition facts, and

- safe handling instructions

The Labeling Requirements Guide states that this information must be prominent and conspicuous, and “in such terms as ‘to render it likely to be read and understood by the ordinary individual under customary conditions of purchase and use.’”

There are other considerations to consider as well, such as meat Country of Origin labeling. According to the guide, “FSIS requires imported meat and poultry products to bear the name of the country of origin, preceded by the words ‘Product of.’”

The Labeling Requirements Guide breaks down all meat labeling requirements in greater detail.

What are the mandatory labeling requirements for produce?

According to the Produce Marketing Association, the produce industry uses various labels “for price identification, inventory tracking and category management,” which “can indicate the brand, variety, country of origin, a barcode and other information.” Specific labeling requirements differ between trade items, like cases and pallets, and the consumer units sold in stores.

Nutrition labeling for raw produce is voluntary, according to the Food and Drug Administration (FDA).

Produce suppliers should be aware that labeling requirements for produce may vary from country to country.

Importance of food labeling requirements for meat and produce

Proper meat labeling and produce labeling is important for several reasons. For consumers, it provides useful information that can help them make more informed decisions about what they eat and help keep them safe; meat labels, for example, are required to include nutrition facts and safe handling instructions.

For suppliers, correct labeling helps ensure that there is traceability in the supply chain. According to Packaging Labeling, if there is a problem with a product, a barcode and/or identification number on the label can be used to trace the product from the customer “back through the manufacturing, shipment, delivery, and raw material purchasing process such that the supplies of the original raw material can be identified.”

Of course, ideally these types of issues would be avoided altogether, as recalls can be costly and damage the brand reputation of the manufacturer. Again, this comes back to proper labeling; according to Food Engineering Magazine, more than 60 percent of FDA recalls are due to labeling issues, including poor quality barcodes, missing or incorrect information, and improperly positioned labels.

Improving the Efficiency of Meat Labeling and Produce Labeling

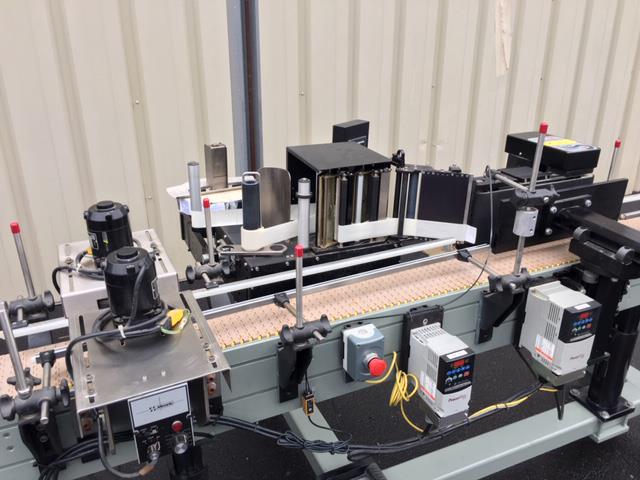

Companies interested in creating the most accurate labeling process for meat, produce, and other food products should consider an automatic labeling system. Transitioning from manual labeling to a labeling machine can create a faster and more efficient process that is less likely to be impacted by human error.

With print and apply machines, for example, a crisp, clean label with the proper information can be printed and smoothly applied to either an individual item, such as a package of meat, or to a larger case, tote, or pallet.

At Paragon Labeling, our labeling machines can be configured to label for a variety of labeling applications because our products use a modular and flexible design that allows you to reconfigure your labeling system as your needs evolve, without needing to buy a whole new system. We understand the unique labeling requirements of food and beverage companies and have labeling expertise for a wide variety of food products, including meat and produce.

Interested in learning how a labeling system can help streamline your meat or produce labeling? Contact our labeling experts to learn more.